+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

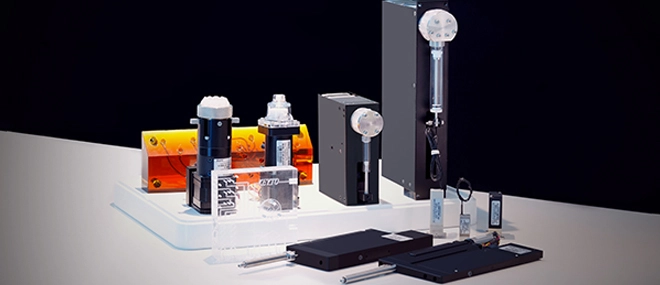

Diaphragm Solenoid Valves are an essential component in the IVD, ensuring precise and efficient control of fluid flow. Keyto Solenoid Valves are crafted with precision and adhere to rigorous medical standards. These valves are designed with a flexible diaphragm that provides a tight seal and prevents fluid leakage. Our Diaphragm Solenoid Valves are available in a range of models to suit your needs and are sure to deliver results that exceed expectations. Trust Keyto for all your solenoid needs and experience the difference in precision and reliability.

Miniature Proportional Valve

A proportional valve is a new type of hydraulic control device. On the ordinary pressure valve, flow valve, and directional valve, the proportional electromagnet is used to replace the original control part to continuously and proportionally control the pressure, flow, or direction of the oil flow according to the input electrical signal. Proportional valves generally have pressure compensation performance, and the output pressure and flow can not be affected by load changes.

The proportional valve performs continuous step control according to the proportion and automatically compensates and controls the target according to the information collected according to the actual situation. The valve opening direction, opening amount, or spring setting force are all follow-ups, realizing a series of continuous and controllable follow-up actions.

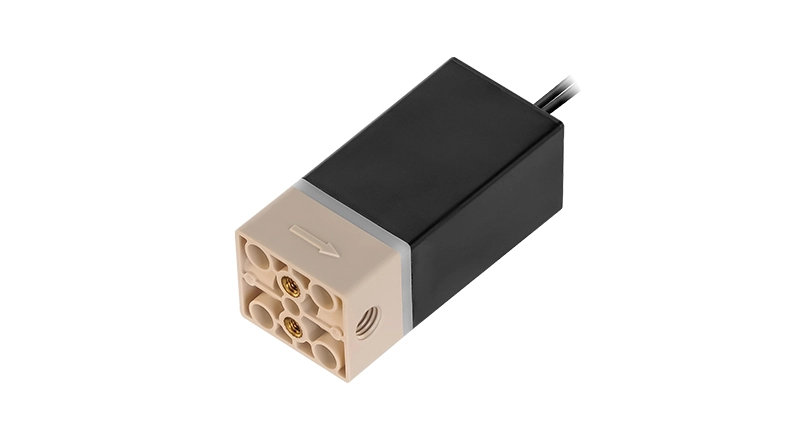

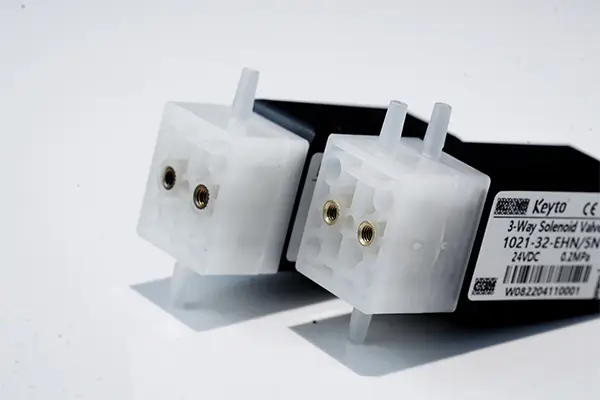

Micro Diaphragm Solenoid Valve

The ordinary solenoid valve is a single action on-off valve, which can't perform continuous step control in proportion. Its valve opening direction, opening amount, or spring setting force are all fixed and cannot be changed according to the actual situation.

When the diaphragm solenoid valve is in the closed state, under the action of the spring force and the gravity of the valve core, the sealing surface of the valve core sealing block is in close contact with the annular plane of the valve seat. Since the annular plane of the valve seat is tiny, the sealing surface of the valve core forms a small annular sealing belt, which plays a good sealing role. When the coil of the small solenoid valve is energized, the valve core moves upward against the pressure of the spring force and the self-weight under the electromagnetic energy. At this time, the sealing surface of the valve core is separated from the valve seat, the pipeline is connected, and the medium flows out through the valve core hole; When the coil is powered off, the attractive electromagnetic force of the coil disappears, and the valve core moves downward under the action of the spring force to close the air circuit.

Solenoid valve function: it is a cut-off valve that automatically opens and closes by electromagnetic force. It is mainly used as an automatic basic device for controlling objects and belongs to the actuator. Usage: it can be used in an industrial control system to regulate medium direction, flow, speed, and other parameters, so it is widely used in various production fields. Most of Keyto's solenoid valves are used in IVD or medical terminals.

The micro diaphragm valve needs to be energized through the circular motion of the motor and the mechanical device to form pressure so that the diaphragm inside the pump makes the reciprocal motion and the air in the pump cavity compress and stretches. Under the check valve, a positive pressure is formed at the drainage port; a vacuum is created at the pumping port, thus forming a pressure difference with the outside atmosphere. Under this pressure difference, water is pressed into the water inlet and discharged from the drainage port. Under the action of kinetic energy transmitted by the motor, water is continuously drawn in and discharged, forming a relatively stable water flow.